Don't get me wrong. They're a brilliant invention to assist automation and prevent screwdrivers from slipping off screw heads - damaging furniture, paintwork and fingers in the process. Interestingly they weren't invented by Mr Phillips at all, but by a John P Thompson who sold Mr P the idea after failing to commercialise it. Mr P, on the otherhand, quickly succeeded where Mr T had failed. Incredible isn't it. You don't just need a good idea, you need a great salesman and, more importantly, perfect timing to make a success out of something new. Actually, it would seem, he did two clever things (apart from buying the rights). He gave the invention to GM to trial. No-brainer #1. After it was adopted by the great GM, instead of trying to become their sole supplier of Phillips screws, he sold licenses to every other screw manufacturer in the world. A little of a lot is worth a great deal more than a lot of a little + vulnerability (watch out Apple!).

My gromble is about the plethora of slightly different depths, angles and widths of grooves that countless bastard manufacturers have adopted ever since, presumably to avoid paying that license fee. The result is a huge number of different types of 'Phillips' or 'crosshead' screwdrivers and bits needed by every handyman in the world - instead of just one! Why on Earth didn't the bloody screw manufacturers standardise on one design? Instead the world is littered with screw heads that have been gouged out by poorly fitting screwdrivers, rendering the screw impossible to tighten and impossible to remove.

Interestingly, Mr P deliberately invented the screwdriver to 'pop-out' of the head to prevent over-tightening and stripping the socket. This always presupposes that you've got the right screwdriver head in the right screw at the time - which of course you invariably do not.

Here's some more info for the seriously screwy (and apologies for Blogger's rubbish template colours):

My gromble is about the plethora of slightly different depths, angles and widths of grooves that countless bastard manufacturers have adopted ever since, presumably to avoid paying that license fee. The result is a huge number of different types of 'Phillips' or 'crosshead' screwdrivers and bits needed by every handyman in the world - instead of just one! Why on Earth didn't the bloody screw manufacturers standardise on one design? Instead the world is littered with screw heads that have been gouged out by poorly fitting screwdrivers, rendering the screw impossible to tighten and impossible to remove.

Interestingly, Mr P deliberately invented the screwdriver to 'pop-out' of the head to prevent over-tightening and stripping the socket. This always presupposes that you've got the right screwdriver head in the right screw at the time - which of course you invariably do not.

Here's some more info for the seriously screwy (and apologies for Blogger's rubbish template colours):

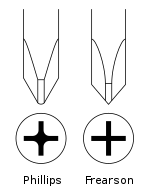

The rounded, tapered slots of the Phillips head were deliberately designed for the screwdriver to "cam out" (pop out) of the screw head recess under high torque on high-speed factory assembly lines.[5] This prevents stripping damage to the screw threads, at the expense of possible damage to the recess in the screw head. This design feature is effectively obsolete, since modern torque-limiting power driver tools eliminate over-torquing damage much more reliably. Market inertia and ignorance of the design's historical intent have led to widespread misapplication of Phillips head fasteners in applications where cam-out is not desirable. Some Phillips head screwdrivers have been manufactured with hardened "anti-cam-out" (ACO) grooves in an attempt to defeat this designed-in behavior.[6]So a pox on every screw maker (except presumably one). Standardise on one design, and bloody stick to it.... so our screwdrivers (sorry, screwdriver) can too.Reed and Prince, also called Frearson, is another historic cross-head screw configuration. The cross in the screw head is sharper and less rounded than a Phillips, and the bit has 45° flukes and a sharper, pointed end. Also, the Phillips screw slot is not as deep as the Reed and Prince slot.[7][8][9] In theory the different size R&P screws will fit any R&P bit size.[10]

Pozidriv is the de facto standard in Europe and most of the Far East. While these more bluntly tipped drivers and seemingly "sloppy cross" screws seem to look more like Phillips, the Pozidriv design also allows for higher torque than Phillips. In fact it is often claimed that they can apply more torque than any of the commonly used crosshead screwdriver systems due to a complex fluting (mating) configuration.

Japanese Industrial Standard (JIS) cross head screwdrivers are still another standard, often improperly referred to as "Japanese Phillips". Compatible screw heads are usually identifiable by a single raised dot or an "X" to one side of the cross slot. This is a screw standard throughout the Asia market and Japanese imports. The driver has a 57° point with a flat tip.[11]

Thank's for sharing Phillips screws. Everything I fully expected of these tools. Great review! I will also trying visit this site.

ReplyDeleteNice post

ReplyDeleteThe most common type of screwdrivers are the Phillips and the flat head screwdriver. However, there are unusual screwdrivers that are useful to have around.

ReplyDeleteIf you have ever tried to take apart the Wii U I am sure you have noticed that there are screws holding it together that require a Y-shaped screwdriver to take them out. These type of screws are known as tri wing screws and are sometimes called the Nintendo screw. My Blog

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteI really enjoyed your article, thank you for the useful content.

ReplyDeleteMy aunt's husband was born in 1898 and raised in Albany, Oregon. He would have been in high school about 1911-1916. He was always firmly convinced that one of his high school shop teachers had later invented the Phillips screw. I am unable to find any Albany connection for either Phillips or the credited inventor, Thompson, although both were living in Portland, about 75 mi. away, at the time of the patent filings. I wonder if anyone out there knows of an Albany, OR connection for either one?

ReplyDelete